新時代の検査トレンド!

CT型インラインX線検査装置

VT-Xシリーズ

Introducing the VT-X950

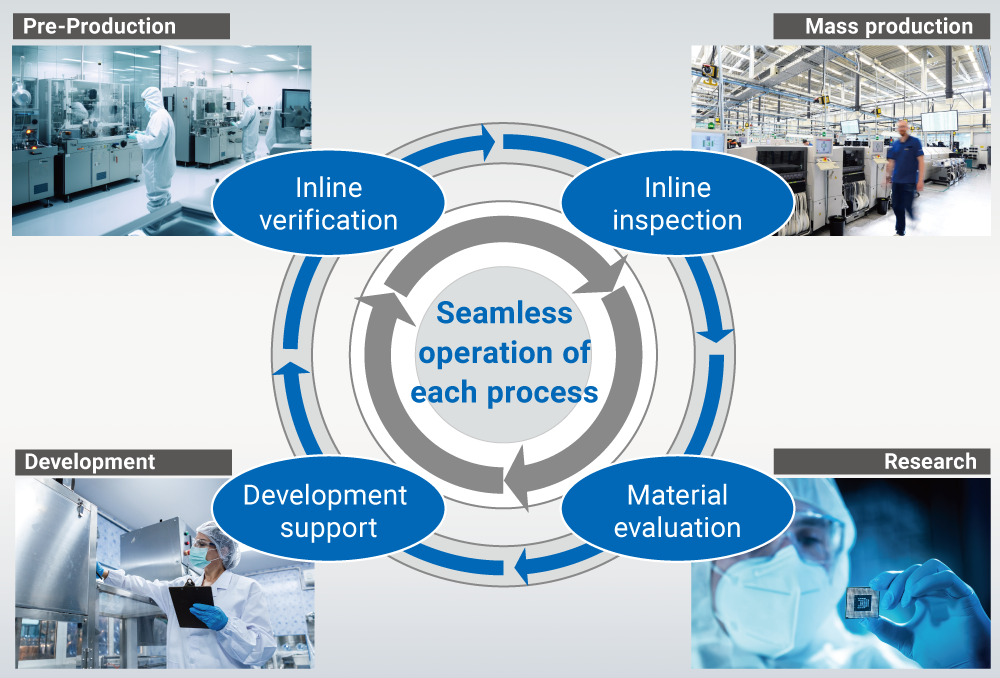

Inspection solutions for 3D packaging for the semiconductor industry

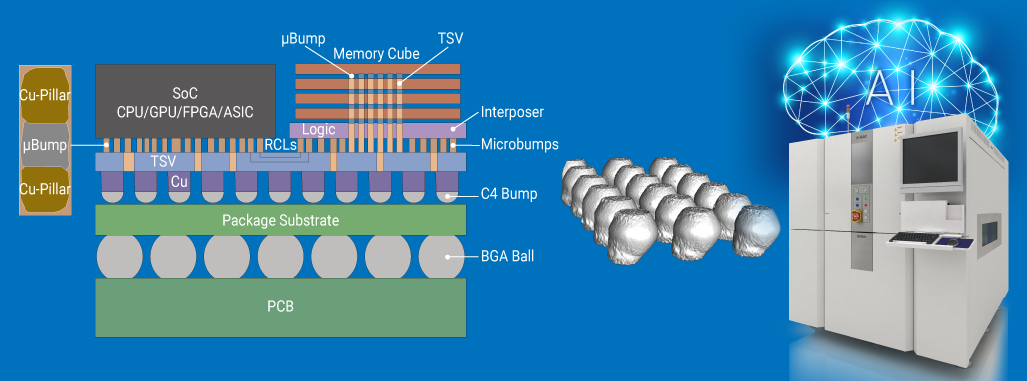

With the practical application of heterogeneous computing*, chiplet technology is evolving year by year. OMRON's AXI VT-X950 series is used for quality control of the solder mounting process of C4Bump and μBump, which are indispensable for 3D mounting (3D-IC), and for yield improvement by feeding back measurement data.*Heterogeneous computing: Computation on a computer system built with a combination of different types of processors.

Productivity improvement

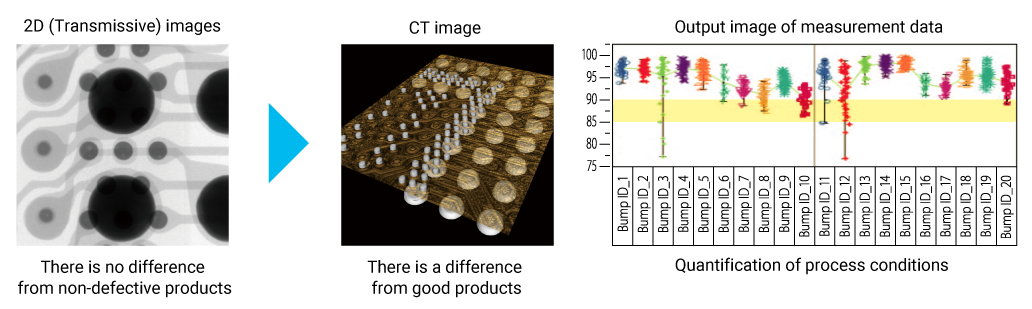

OMRON's unique high-speed imaging technology and automatic inspection technology achieve stable measurement. Statistical analysis of measured data helps to improve productivity by managing process capability and providing feedback to the manufacturing process.

Versatile applications

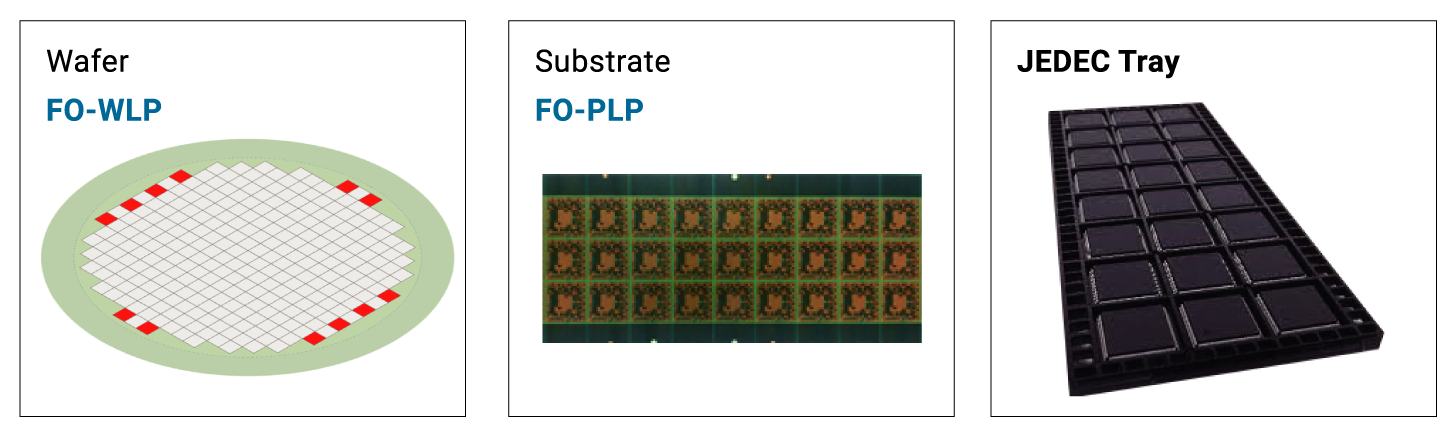

Automated inspection of wafers, substrates, JEDEC trays, and other conditions is possible.

By registering the measurement position and inspection position in advance and setting the inspection recipe, it is possible to perform automatic inspection of multiple PCB repeatedly.

Introductory video

High-definition CT images, which are indispensable for void measurement, can be captured and inspected at high speed.

In addition, the measured 3D data can be observed

in any slice and direction.

Automatic inspection of 3D mounted parts is possible.

Even with multiple layers, stable inspection is possible

without the influence of other layers.

It is possible to check the quality of the solder mounting process

of μBump and C4Bump, and to guarantee the inspection

of all products including BGA balls.