Advanced Motor Condition Monitoring Device K7DD

Capture a wide variety of abnormalities affecting motor equipment to minimize unplanned downtime

センサ

センサ

FAシステム機器

FAシステム機器

モーション/ドライブ

モーション/ドライブ

ロボティクス

ロボティクス

セーフティ

セーフティ

スイッチ

スイッチ

リレー

リレー

コントロール

コントロール

電源/周辺機器他

電源/周辺機器他

省エネ支援/環境対策機器

省エネ支援/環境対策機器

全ての商品

全ての商品

ファイバセンサ

ファイバセンサ

光電センサ

光電センサ

変位センサ/測長センサ

変位センサ/測長センサ

画像センサ

画像センサ

コードリーダ/OCR

コードリーダ/OCR

近接センサ

近接センサ

振動センサ/漏液センサ/その他センサ

振動センサ/漏液センサ/その他センサ

全ての商品

全ての商品

マシンオートメーションコントローラ

マシンオートメーションコントローラ

データフローコントローラ

データフローコントローラ

産業用PCプラットフォーム

産業用PCプラットフォーム

多軸モーションコントローラ

多軸モーションコントローラ

プログラマブルコントローラ

プログラマブルコントローラ

ソフトウェア

ソフトウェア

ネットワーク機器

ネットワーク機器

プログラマブルターミナル

プログラマブルターミナル

RFIDシステム

RFIDシステム

全ての商品

全ての商品

インバータ

インバータ

サーボモータ/サーボドライバ

サーボモータ/サーボドライバ

全ての商品

全ての商品

協調ロボット

協調ロボット

モバイルロボット

モバイルロボット

産業用ロボット

産業用ロボット

全ての商品

全ての商品

セーフティライトカーテン/マルチビーム/シングルビーム

セーフティライトカーテン/マルチビーム/シングルビーム

セーフティレーザスキャナ

セーフティレーザスキャナ

セーフティドアスイッチ

セーフティドアスイッチ

プログラマブルセーフティコントローラ

プログラマブルセーフティコントローラ

セーフティユニット/セーフティリレーユニット

セーフティユニット/セーフティリレーユニット

全ての商品

全ての商品

全ての商品

全ての商品

一般リレー

一般リレー

全ての商品

全ての商品

温度調節器(デジタル調節計)

温度調節器(デジタル調節計)

カウンタ

カウンタ

全ての商品

全ての商品

パワーサプライ(電源)

パワーサプライ(電源)

状態監視機器

状態監視機器

接続・省配線機器

接続・省配線機器

検査装置

検査装置

全ての商品

全ての商品

電力監視

電力監視

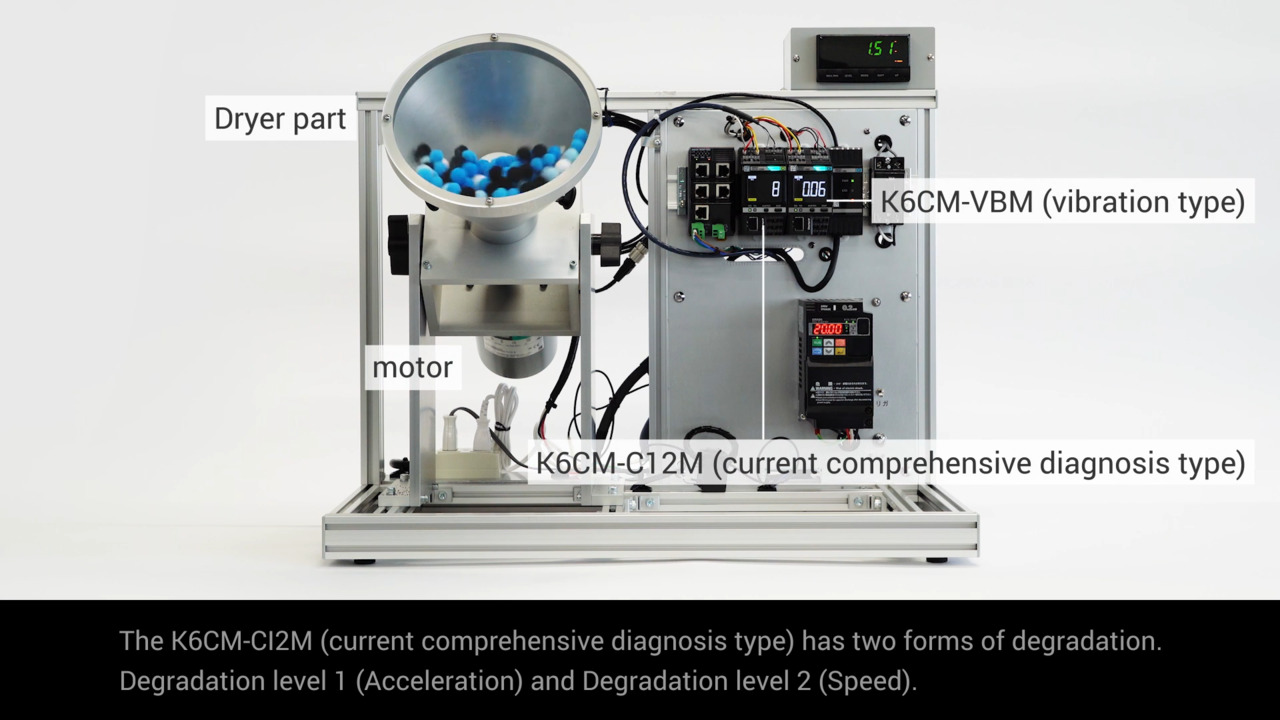

This movie uses a demonstration kit that is built by a drying furnace image

Capture a wide variety of abnormalities affecting motor equipment to minimize unplanned downtime

The K6CM's unique algorithm detects abnomalities in powder sticking to the wall surface.

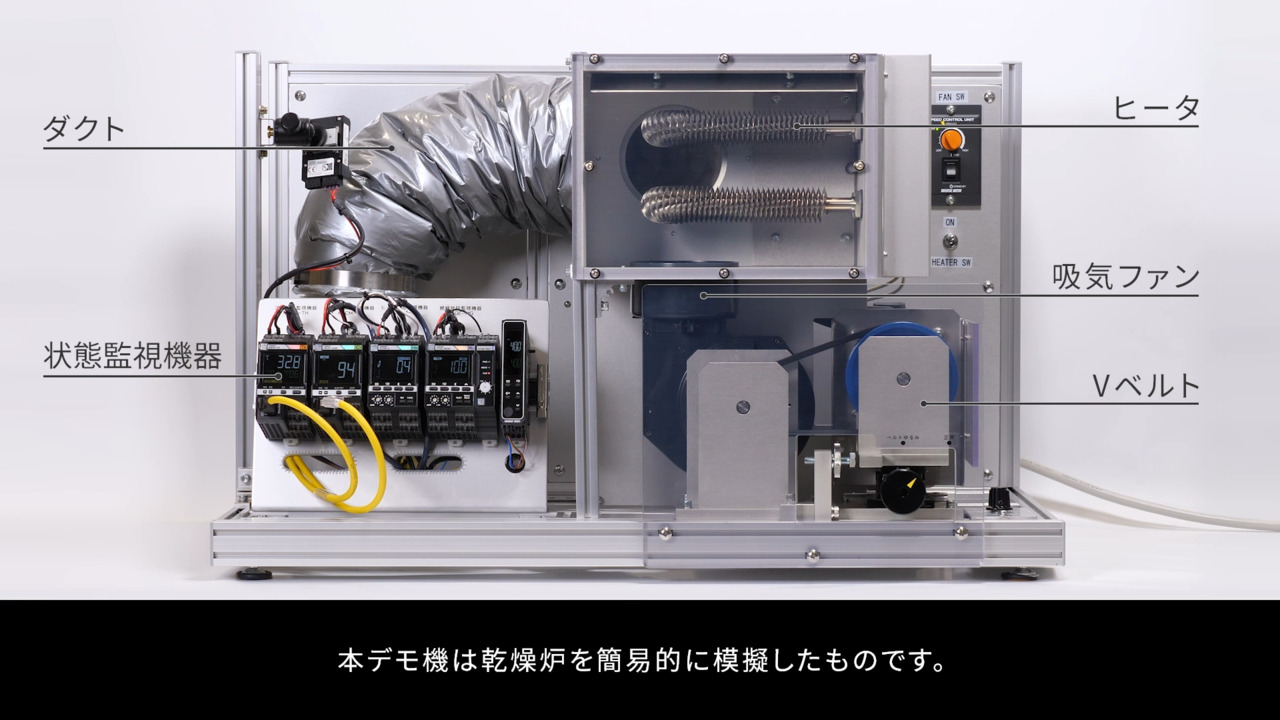

この動画では乾燥炉をイメージしたデモ機を使って、設備の複数の構成機器を網羅的に監視できる状態監視ソリューションを紹介します。

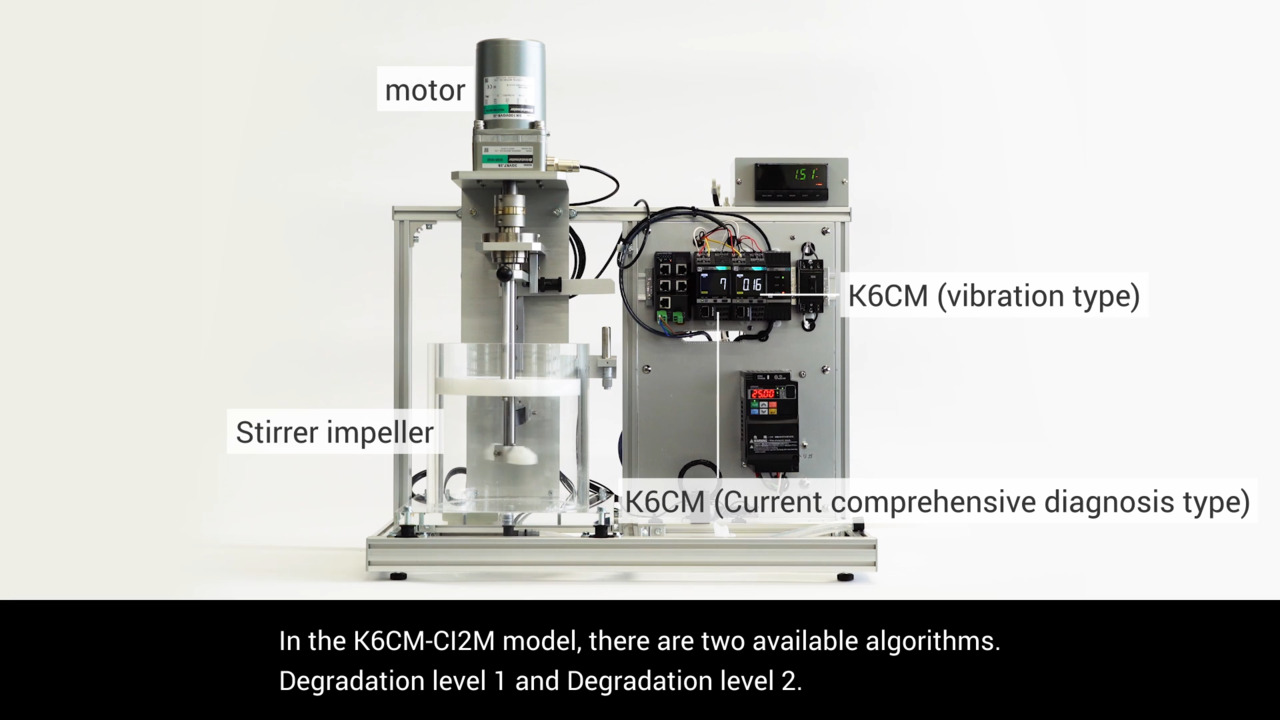

The K6CM's algorithm detects contact between the impeller of the mixer and foreign matter.

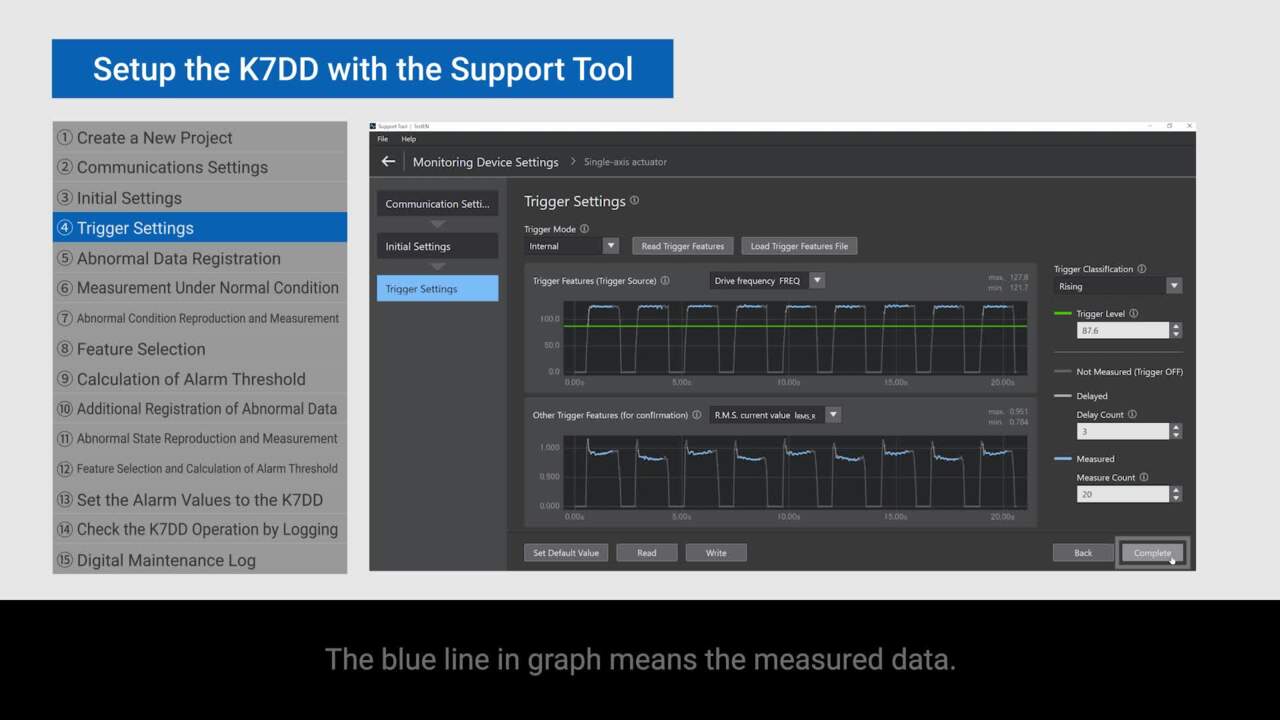

This video describes the K7DD setup procedures; Unpacking, Installation, Wiring, and the setup with the K7DD support tool

Belt aligment is detected by monitoring the motor current with the K6CM-CI2M