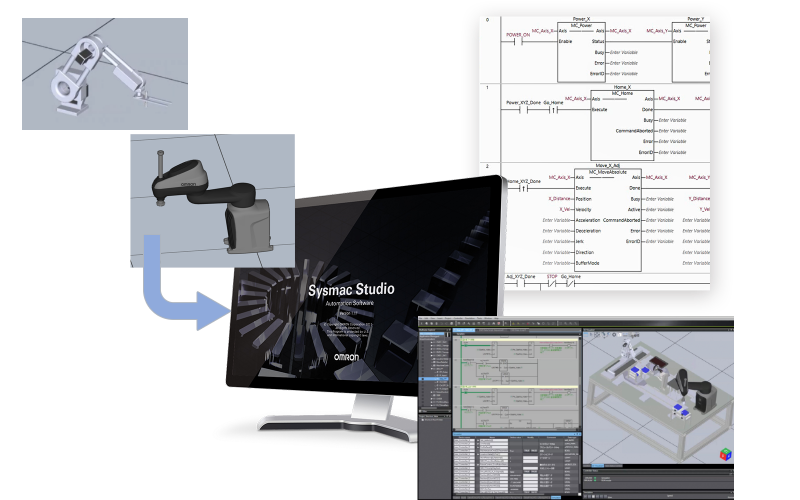

Complex and short-term development

Diversified products and short product lifecycle require more complex and faster development of production equipment.

Shortage of engineers

Global shortage of labor and soaring labor costs make it difficult to recruit engineers.